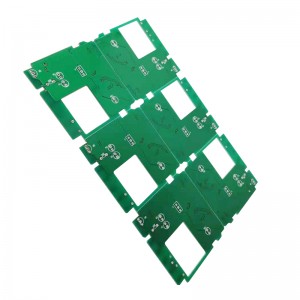

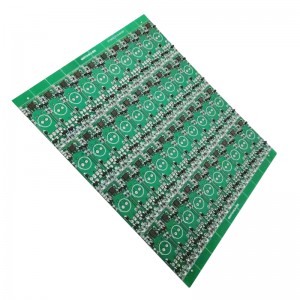

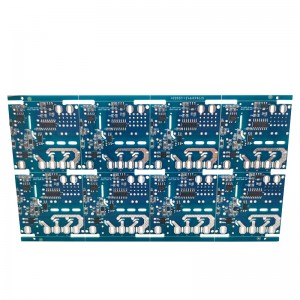

One Stop Service SMD SMT Electronic Circuits Board Assembly Services PCBA

Why choose us?

Founded in 2014, Wenzhou LMO Electrical Appliance Co., Ltd. is a professional manufacturer of SMT chip processing, DIP, post-welding, testing, and assembly of electronic products. Mounting range: For all kinds of electronic components, QFN, BGA, modules and other special-shaped components, the minimum mounting specification: 0201, BGA spacing is greater than 0.3mm, and it can be processed by patch. Process requirements: solder paste, red glue; lead-free process for processing. Processing range: security, electronic products, wireless chargers, sensors, 3D printing pens, sporting goods (skip rope counters), Bluetooth modules, module motherboards, mobile power boards, tablet computers, surveillance cameras, LED drive power, LED light bars, LED strips, flexible boards, LCD TV boards, LED displays and other products. Production capacity introduction: 5 fully automatic SMT production lines, 3 plug-in post-welding lines, 4 assembly lines, 80 front-line employees, and 80% of employees with more than 2 years of work experience on the production line; rich experience and sophisticated production technology . The daily standard production capacity of SMT is 5 million points, and the daily standard production capacity of post-welding line is 200,000 points, with a pass-through rate of 97%.